Aseptic Filling

Precision, Compliance, and Flexibility for Vial-Based Drug Products

At BAG Health Care, aseptic filling is our core expertise. We provide GMP-compliant fill and finish of sterile parenteral drugs in vials from 2R to 50H—ideal for clinical and commercial production.

Our Annex 1-compliant filling line (Bausch + Ströbel) and small-scale Rota filler support volumes from 1.2 L to 200 L, with filling speeds up to 6,000 vials/hour using precision piston pumps. We handle dead volumes under 500 mL, maximizing yield for early-phase and high-value biologics.

We manage the full process—from tech transfer to validation. Dedicated project managers ensure clear communication and regulatory-compliant protocols for IMPD or MAA filings.

Your point of contact

Lyophilization

Scalable Freeze Drying with Industrial Expertise

We offer GMP-qualified lyophilization for biologics, peptides, and sensitive actives. With three freeze dryers (4, 8, and 17 m²), we support batch sizes from 500 to 70,000 units (2R), covering early-phase to commercial production.

Our equipment handles complex formulations, including those with organic solvents. We collaborate with your team to industrialize and optimize the freeze-drying process from development to GMP scale-up.

Your point of contact

Analytical Services

Science You Can Trust, Results You Can Act On

Our in-house labs support the full lifecycle of parenteral drug products, from raw material testing to release and stability studies.

Capabilities include:

For specialized testing (e.g. LC/MS), we work with audited partners. We offer method development, transfer, and identity verification to ensure product safety, stability, and compliance.

Your point of contact

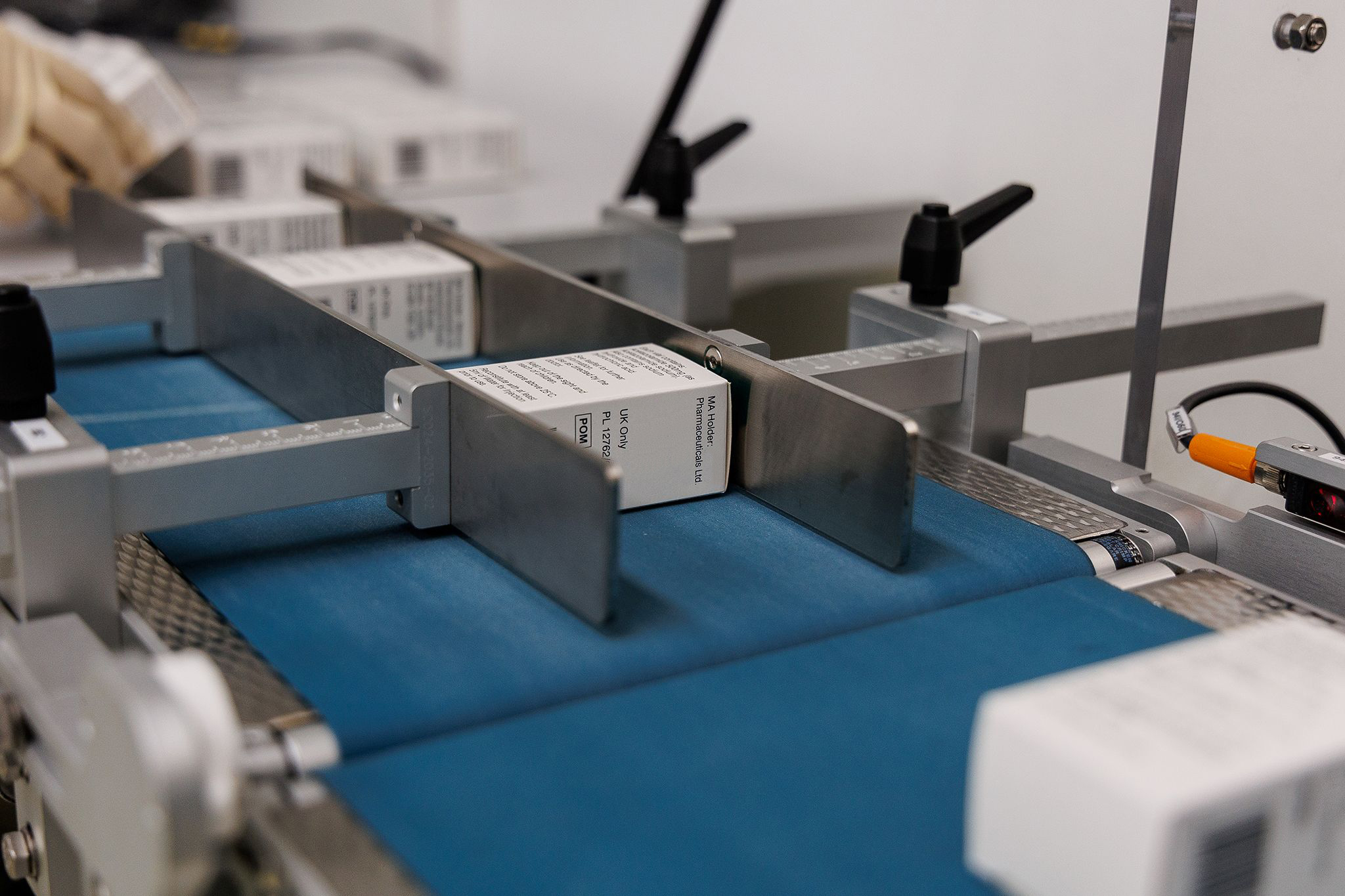

Secondary Packaging & GMP Storage

Safe, Secure, and Ready for Shipment

After production, we handle secondary packaging and GMP-compliant storage to simplify your logistics and ensure supply chain integrity.

We provide labeling, boxing, and carton packaging for clinical and small commercial batches, including EU serialization (2011/62/EU).

Storage options include:

Integrated packaging and storage ensure your product remains safe and compliant from fill to final delivery.

Your point of contact

Regulatory Compliance & QP Release

Confidence Through Quality

Regulatory compliance is our foundation. We hold full GMP approval for clinical and commercial manufacturing, including Annex 1 adherence and QP services.

Each GMP batch undergoes 100% visual inspection and container closure integrity testing (CCIT). Our QPs manage batch release and issue CoAs or CoCs.

We support:

We handle validation, CQA/CPP assessments, and documentation—keeping you audit-ready.

Your point of contact

Technology Transfer & Project Management

From Kickoff to Commercial Launch

We ensure smooth technology transfer with a structured, collaborative approach tailored to your needs.

Our process includes:

Choose your level of involvement—from joint collaboration to full-service management, including deviation handling, validation coordination, and submission support.

We don’t just fill vials—we bridge gaps with expertise and reliability.